I needed another corded mouse and this time around I thought of @PKL@mastodon.social and @pronk@mastodon.social instead of Logitech’s shareholders. These guys make open source mice among other open source hardware under the brand Ploopy. You can order one from them, assembled or as a kit, or you could print and build it entirely by yourself.

The mouse itself is pretty great. Coming from a long line of Logitech (MX518/G5/G500/G502), it’s a bit larger than what I’m used to but I think I’m getting accustomed to it.

Here’s another shot of it:

Ew

Is it comfortable in the hand? The surface looks super rough

It feels good. I’m thinking of smoothing it with epoxy but it’s not necessary.

Only as good as your 3d printer and settings I’d say

Looks like a bitch to clean. Gonna get all sorts of grease collecting in those grooves…

Theoretically, you can mold it to fit your hand but the tolerances and mountings make that a hassle.

As for the print itself? Most people just do a quick print and have the telltale ridges from layers. But you can futz with settings to improve the smoothness or just finish the print itself. At which point it is not going to be as smooth as injection molding but it will be more “different” than “bad”.

Stupid question from someone who’s never 3d printed anything - can you just sand these things smoother?

It depends how it was printed.

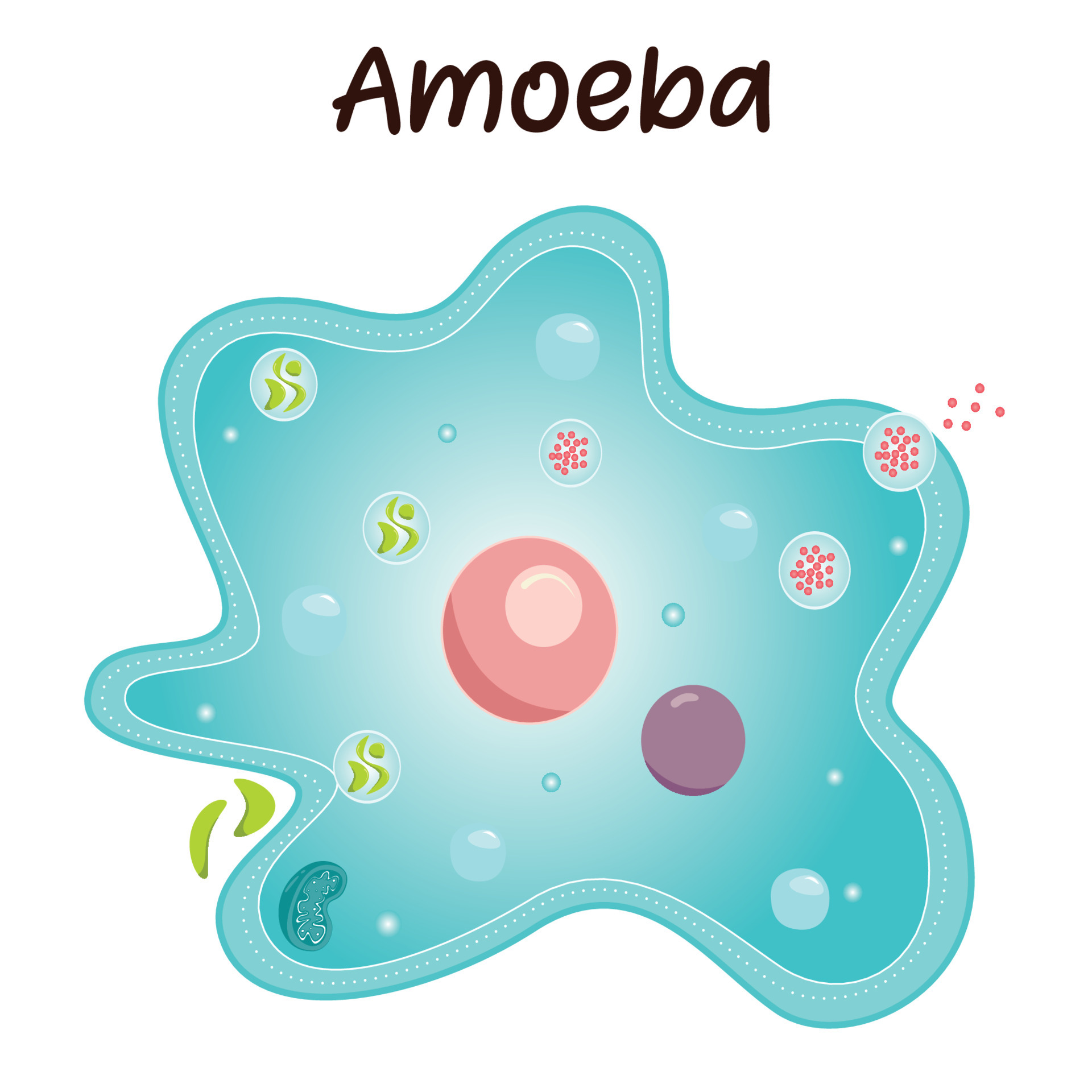

As a SUPER simplified basic: Any 3d print consists of walls/perimeters and infill. The walls are the exterior surfaces of the print. The infill is what is inside. And the vast majority of prints tend to be sparse infills. So rather than solid plastic beneath those walls, you mostly just have air and a mesh structure of some form.

So if the wall is thick enough (generally referred to as “number of walls”)? Sure. If it isn’t? You’ll just see the void inside the shell itself and make things much worse.

What is generally done to reduce “3d printed texture” is a mixture of smaller print layers (so the ridges are much thinner), printing with more walls, and actually lightly melting the exterior surface (either through chemicals or heat).

VKB are probably the kings of the mid-range sicko HOTAS market and I am like 90% certain they 3d print the shell of their sticks for the Gladiator (?). But they do such a good job that I genuinely can’t be certain. Whereas the vast majority of ploopy builds… aren’t that.

All Ploopy’s stuff looks rough. I think they’re 3D-printing them. Maybe one day they’ll progress to something that gives a nicer result.

I was looking at their trackballs but the ambidextrous ones look awkwardly tiny and have rattly bearings, in addition to the rough finish. I support what they’re doing but I wish the products were a bit less prototypey.

It looks rough, but it’s actually fairly comfortable.The only bit that bothered me was the edge of one of the buttons, and a nail file fixed that in seconds.

I think they’re 3D-printing them. Maybe one day they’ll progress to something that gives a nicer result

Yes they are 3D printed

Poorly 3D printed.

The layering issue could be solved by orienting the object at a 45° angle

I could reprint the housing one day, when I get a printer myself. 😂

Or even smaller layer height. That looks like .2 or .24 minimum.

Yeah, definitely 3D printed.

The whole point is that it’s open source and they want people to be able to print them themselves.

What is your experience with the scroll wheel? Some time ago I was interessted in a Ploopy but the non clicky scrollwheel put me off.

It’s alright. It’s not as nice as the flywheel/clickwheel on G502 but it’s alright. It doesn’t accidentally spin for me so far. I imagine one of the custom buttons could be used to enable/disable scrolling along with some script, if it becomes a problem.

My scroll wheel was very stiff and irritating at first. It did loosen over time and is now completely useable. It doesn’t free-spin, but it also doesn’t take a lot of force to move.

The lack of clicking is a little disconcerting, but not a deal-breaker for me. I guess you could add an extra part to make it click — like putting a playing card in the spokes of a bicycle wheel.

Because I bought the trackball mouse, I changed the trackball to scroll when a button is held. I now have horizontal and vertical scrolling, and don’t use the scroll wheel except for middle clicking.

I have the same mouse, and that scroll wheel is unusable. It requires a ton of effort to just scroll tiny amounts because the sensitivity is waaay too low and it cannot be adjusted. The rest of the mouse is really nice because it runs QMK.

I set up drag scrolling as a workaround for the shitty scroll wheel, which allows you to press a button (or a combination of buttons) and then use the mouse’s optical sensor as an omnidirectional scrolling device until you release the button.

I set that up on my Ploopy Adept hand trackball mouse as well. It’s my favorite mouse I’ve ever used.

These jokers are charging $130CAD for a mouse, what in the fuck

You don’t need to pay them anything.

You can just download all the files they’ve made available and build one yourself. The electronics have full schematics so you can either make it yourself or send the schematics to a PCB company. The shell is entirely 3d printed. All extra hardware is readily available.

If that sounds like a lot of work, maybe it’s worth paying the person who created it and is offering to do all that work for you.

It’s hand crafted, they probably barely breakeven.

Go ask Logitech if they will share blueprints or spend 0.10$ extra for a button that survives more than 100’000 clicks

I have a Logitech from 2003 or so. The feet are gone. The plastic under the feet is rubbed rmooth. The Omron switches are still great, no failure symptoms. Meanwhile I replaced a G500 after couple of years of use due to a switch developing “double-click” from wear. The reason I needed another wired mouse now is that another Logitech developed double-clicking. So yeah, exactly.

I have a 2 year old MX Master 3S, the left click button can’t dragndrop anymore without dropping, unless you press really hard on it.

Also I can’t rebind the buttons without having Logitech spyware installed on my computer.

Changing the button requires soldering and deep disassembly.

For a 120$USD mouse this sucks !Using cheap switches on high end stuff like this is just abominable. I’d somewhat understand it on a cheap model but this… fucking hell.

How else would they still stay in business if I could just use that mouse for the next 10 years !

If it only was merely aboit staying in business… instead it’s all about growing profits. They made $613M on $4.3B last year.

Chatgpt, give me the most business answer possible with airtight logic that eliminates the possibility of imagining a different way.

Chatgpt :

Logitech, like any publicly traded company, exists to maximize shareholder value, not product longevity, so using cheaper switches—even in a $120 mouse—isn’t corner-cutting, it’s strategic. A $0.10 upgrade per unit sounds trivial, but across millions of units it erodes margins significantly, and more durable components risk extending the product lifespan beyond the optimal refresh cycle, cutting into predictable repeat sales. Making switches hard to replace and binding functionality to proprietary software isn’t anti-consumer—it’s deliberate lock-in that ensures brand dependency and data capture, both of which are monetizable assets. With shareholders expecting year-over-year growth, not stability, any move that delays repurchase or encourages repair undermines the core business model. The $613M profit on $4.3B revenue isn’t greed—it’s the result of a finely tuned system where every design and pricing decision serves one purpose: sustainable, scalable profitability.

I had 2 Logitech m570s fail on me before I bought the Ploopy Thumb. So far it’s lasted longer than either Logitech mouse, and looks like it will manage to be my longest surviving mouse.

“These jokers” are giving the files and documentation away for free. They’re charging for the cost of putting together a kit so you can build one without thinking or understanding anything. If you want it for cheap, self source and DIY, that’s the whole point, that’s why the files are free.

How much should it be? It uses a great sensor, Omron main switches, it’s built by two guys in Toronto, Canada where rent isn’t cheap. There’re definitely cheaper massproduced mice that don’t share IP for free. This isn’t that.

You need plastic that is more resistant to contact so that you don’t end up covering your hand in microplastics. That material looks like questionable recycled plastics.

I’m also not giving up on wireless. I’d rather have an only bluetooth (slow?) mouse than a wired one.

All the 3d printed parts have files available online. You can 3d print new parts using any material you want.

As far as I’m aware, PLA is mostly safe, but every company has different proprietary additives.

Something plant based like cellulose would be nice. Longevity wouldn’t be a concern with how easy it is to reprint and reassemble.

Wireless would be nice.

Or titanium? But that would probably require midifications of the bendy bits to keep them flexible. 😂

I kinda like the idea of using an anvil to smith a computer mouse, but I don’t have such tools. Perhaps carving the shapes from wood would be easier.

I’m not sure what makes it seem recycled, seems like a reasonably fine print to me. I believe it’s printed in PLA which personally I’d want to see PETG but that’s more for long-term durability than microplastic concerns, which I can’t speak to.

I keep thinking I should give a ploopy a shot but I’ve increasingly grown to like/need vertical mice and, like most ploopy related efforts, it is mostly “you CAN do it” with nobody ever having even tried because it requires pretty hefty redesigns of almost every part to mount things correctly.

I bought a Ploopy Thumb a few years ago. I assembled it myself, and was pleasantly surprised at how easy it was (when actually following the instructions).

The small button on the right has broken twice, which wasn’t a problem because I just downloaded the stl file and reprinted the button assembly.

I wanted horizontal scrolling, so I used QMK to make the trackball a scroll wheel when the right side button is pressed (that may explain the faster button wear). It was surprisingly easy, and there was even a comment in the source code pointing out which line I should modify for horizontal scrolling support. I guess they expected people to want this feature.

The price is high, but I don’t expect to buy another mouse unless my needs change. The open source hardware and software is excellent, making repairability 10/10. The edges of the buttons are slightly rough, but I have the 3d printing files, so I get to choose what material it’s made of and what post processing / smoothing is used. It hasn’t bothered me enough to do anything about it.

While I can’t recommend a trackball mouse to anyone, I can recommend Ploopy. It’s one of the few products that I feel like I actually own.

What I really want is this, but with a trackpad instead of a trackball.

They do have a trackpad, but not in this shape.

I was surprised when I started using the Steamdeck. The Steamdeck’s trackpad felt almost identical to my trackball mouse, and it took effectively no time to get used to it.

The advantage of a trackball over a trackpad is that you can spin the ball for high movement speed, then stop it after a set time for fairly accurate distance. A trackball (or trackpad) will never be as accurate as a regular moue, but it is surprisingly usable (after a few months or practice).

I’ve used several trackballs, but they have all been seriously uncomfortable for me and my specific brand of RSI. My current “mouse” is a Steam Controller, but using it one-handed isn’t great due to the uneven weight distribution. I also have much better accuracy using a trackpad vs a trackball.

Ideally, I just want a Steam Controller cut in half with a more confortable grip that doesn’t dig into my palm.

How do you use a trackball mouse? Does moving the mouse and moving the trackball both move the pointer? Or one moves the pointer and the other does something else?

I helped a user who exclusively uses a trackball and started getting used to it within seconds. My thumb was definitely not used to the trackball but I very quickly adapted and could navigate the computer normally

The mouse stays in one location with grippy feet and the trackball moves the cursor. There is no sensor for mouse movement. It does take a while to get used to.

The reason I chose it was that I didn’t have enough desk space to move a mouse. I barely even had enough space to put the mouse. Now that I’ve moved house, I just like the novelty. It’s not as accurate as a regular mouse.

I would love a mouse that could do both regular movement and trackball movement so I could have 4 axis inputs. Sadly, I haven’t found any like that.

It’s not as accurate as a regular mouse.

This is not true of all trackballs. Some can be more accurate than a mouse with the push of a button.

That may be technically true, but what’s stopping someone from using the same button on a regular mouse?

A regular mouse can have a large amount of movement with your elbow and very fine control with your wrist. Your thumb on a trackball may have more range or precision than either, but not both combined.

My personal experience is that a trackball mouse is a little less accurate when trying to move a large distance precisely. Perhaps I just need more practice.

Do you have a button in your regular mouse that enables precision mode?

I don’t personally have a regular mouse, but most “gamer” mice have a DPI button.

I have seen several pro gamers use the DPI button on their mouse to rapidly change their precision while playing. I suspect it would take more practice than I’m willing to put in, but they seem to use it to great effect.

How’d you make the surface this smooth?

Overuse and poor lighting.

I know some people have used an acetone vapor bath with ABS prints. I’ve never looked into what works with PLA.

LOL, makes sense. I’m considering using epoxy. Seems like there’s a product that can be brushed on. It fills the gaps. Can be painted if desired.

I’d be interested to see how well it works.

I’ll try to remember to post if I end up doing it.

Just to save the heartache, acetone vapor does not work with pla.

No left hand options 😪

Most slicers allow you to mirror parts very easily

The PCB doesn’t look ambidextrous. Maybe there’s a way to mirror that too but it’s probably not as easy. And you’d have to get it custom built.

Ohh OK, yeah that would be tricky unless you’re an EE

Just turn the printer upside down, dummy!

I want one

How do you like the mouse? I got their trackpad and it’s pretty good. I’m thinking about replacing my old Mx Master with their mouse.

I like it. The surface finish is obviously not as nice as the Logitech, but I like it. I’d probably like it better if it were smooth, which I might try achieving with some epoxy paint. The button feel is great. Better than my G502. Tracking is stellar. The shape is comfortable. The infinite/togglable scroll wheel on the G502 is sonething I wish it had but I can live without it. There’s also that special feeling, that someone decent made it, and that it can be infinitely repaired. If it’s not a stretch money-wise for you - get one. In the worst case scebario your money would have gone supporting open source hardware.

Layer lines, too expensive.

Looks less comfortable than one of those 10~15€ brandless mouses at MediaMarkt

Layer lines

You say “free hand grip for less strain” weird.

layer lines can be sanded down during making and/or improved upon massively if you are fine with it taking much longer to print. or own a better printer.

the price is steep, but its pre-made and post processed. i think the real value of it is in making it yourself for the price of the components and raw plastic if you already own a printer.

Ah great! My hands are big and all the mouses I tried are all too small. And it’s giving me rsi. Hopefully this will help me. I theory I can just potentially print my own mouse design that finally fit my hands?

You probably can modify the existing one to fit your hand fairly easily.

The PCB has electrical buttons permanently attached. The 3D printed parts have protrusions that touch the buttons.

You could possibly redesign the 3D printed parts only, but at some size increase you may need to start looking into redesigning the PCB.The good news is that the mouse itself is bigger than the picture makes it seem. You might actually be OK without modifications.

If you do want to give it a try, I highly recommend buying the kit and fully assembling it yourself. That way you know that it works, and you have a solid foundation to apply the modifications to.

Good point. It measures at about 13x8.5cm.

I’ve got to say “Ploopy” is one of the absolute worst names I’ve ever seen. Before I even saw the picture, I thought “I bet it looks like shit.”

Ploopy fills my hand really well

“I like resting my hand on my Ploopy”

It almost sounds like a vintage game sound, like “bleep bloop”, but worse, fecally worse.

It’s like an alien name out of Rick and Morty. 😂

you mean you dont like my plumbus? what about glorp?

it gives me a general “its probably entirely shit”. that’s really a bad name.

After reading up it sounds like a decent product but they should definitely consider rebranding.

Opensource projects often have terrible names.

Gimp, libreoffice, lemmy, Apache… just the ones that come to mind.

the fuck is wrong with LibreOffice?

Gimp is a funny acronym that explains exactly what the software does. Libreoffice also tells you exactly what the product is. Lemmy is quick, catchy, easy to remember, and has a story behind it. Apache is… pretty bad.

Ploopy is literally “poopy” with an extra letter.

Gimp refers to sexual exploitation. Often the “exploited” is a willing participant but often not. Regardless it’s “funny” the way a 12 year old finds drawing dicks on things funny.

Libreoffice only tells geeks exactly what the product is. My team, who uses Libreoffice, couldn’t explain what Libre means, and no one can pronounce it.

Being quick and catchy is a pretty low bar. No one knows or cares about the story behind Lemmy. It sounds silly in conversation.

Gimp refers to sexual exploitation.

Like CBT and dozens of other terms, those damn psychologists and their Cock and Ball Torture.

Libreoffice only tells geeks exactly what the product is. My team, who uses Libreoffice, couldn’t explain what Libre means, and no one can pronounce it.

Not sure if this is serious or not ?

If they’re illiterate perhaps wider reading beyond Manga would help?

Gimp refers to sexual exploitation.

No, it doesn’t.

Libreoffice only tells geeks exactly what the product is.

The target market is primarily geeks.

no one can pronounce it.

Sounds like your coworkers should expand their horizons. Libre is a common word in (at least) 2 widely spoken languages.

Being quick and catchy is a pretty low bar.

Not when you’re naming a product. You think its hard to get people to use Lemmy, imagine trying to sell them on “Federated Link Aggregater Website.”

It sounds silly in conversation.

As does Google, Instagram, and Tiktok but they at least managed to pick silly sounding names that don’t sound like a child trying to describe a loose bowel movement.

I’m sorry but that’s such a ploopy take. You can’t just judge something by it’s name 🙄

Now do printers.

Yes please!

I often wonder how difficult it would be to create an aftermarket control board for existing printers.

pretty stupid that we can print in 3 dimensions well, while 2-dimension remains locked behind capitalism.

I have written a more detailed comment on it before, but 2d printing is much more technically complicated than 3D printing, and the resolution is literally an order of magnitude difference (0.2mm vs <42um) and the printer has to print full color on any surface with microdots in a very very short time. People would throw the printer out if it took 10 minutes for a single paper like a large first layer takes in 3D printing.

We were ok with dot matrix printers. We are and will be ok with black and white prints. Open Source community will be ok with a slow and ugly print. The company just need to allow their monopoly to be broken. I don’t think they will.