The part is a 345mm x 60mm spice rack that mounts to the inside of our pantry door.

About 7 years ago, I made four spice racks out of wood and painted them to match our cabinet door. Wear and tear (and kids) have resulted in them getting glued back together multiple times. I finally gave up, modeled the design, and have been printing replacements in PETG as they fail. So far they’ve been holding up a lot better. They’re also a touch deeper than my original wood design, so they can fit the round spice island containers more easily.

In the past, I had to print these in two halves on my i3 clone (a Monoprice Maker Select Plus, which is a rebadged Wanhao Duplicator i3 Plus). Now that I have a printer with a 350 mm^2 bed, I thought I would see if I could print the rack in one piece. My single ASA attempt was an epic fail due to warping, but the PETG print went very smoothly with very minor lifting. I’ve read others say PETG does not like enclosures, but I’ve printed a number of PETG parts with my Voron fully enclosed and they’ve come out very well. I struggled with PETG warping on larger parts with my unenclosed i3 clone.

Here are a few photos comparing a rack I printed on my i3 clone to this one. The print quality is quite a bit better, but now that I have a higher ceiling to shoot for I’m realizing I have a further to go on my tuning journey. I will say that I never noticed things like the Slic3r buldge, that’s also present in Super Slicer, until now.

I personally find it helpful to see other’s prints under unflattering lighting, so with that said…

Somewhat flattering lighting (eg ambient)

Voron:

i3 clone:

Direct light, provided via a flashlight, perpendicular to the surface

Voron:

I3 clone:

direct light, provided via a flashlight, nearly parallel with the surface

Voron:

i3 clone:

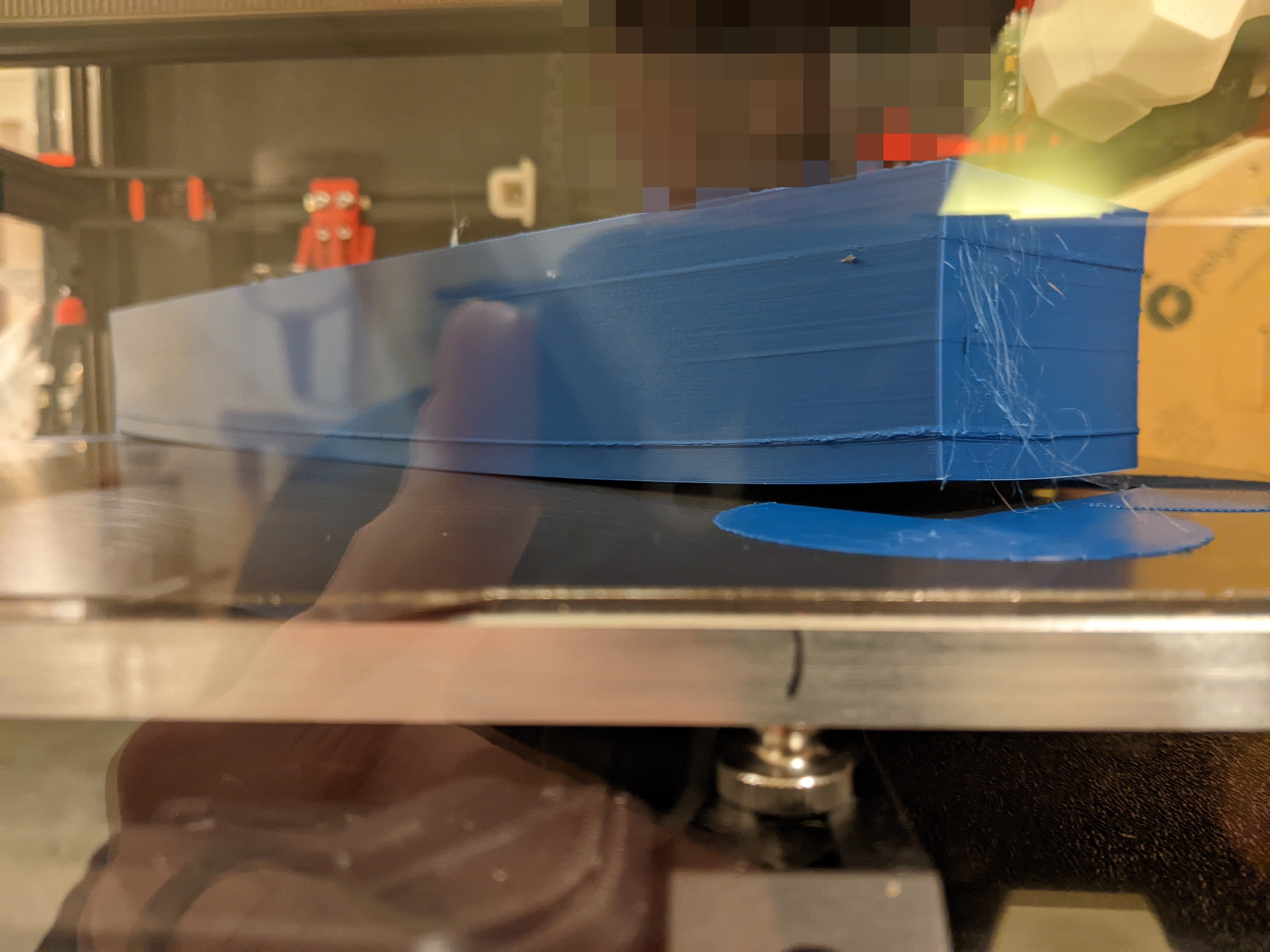

Bonus photo of my ASA attempt

Sadly, I forgot to change my print temp back from 250 to 240, so there’s quite a bit of wispy stringing. I suspect the print would have separated from the bed anyway. Any pointers here would be appreciated. The bed was clean (soap + water), was at 100, I let the printer heat soak for about 45 minutes with the filter going full tilt, first layer squish was solid good, smooth PEI (the textured side seems to have prints come loose more easily).

Surface quality is also driver (+ driver settings) and motor related, and even the combination of them.

This is fair, and is part of what I meant by not being willing to modify the extruder (or the main board) before going off the deep end with the Voron.

I suspect having a gear reduction between the extruder motor and the extruder gear would go quite a ways towards helping. Swapping my Voron from a set screw gear to an integrated gear, that’s molded/pressed onto the shaft, helped too. That’s before even getting into the driver.

Yeah ridga or vzhextrudort style gears definitely help greatly. You could do a mihai style test to see if the artifacts on the i3 are mostly extruder related or from the XY motors.

Tuning drivers consistently for quality is going to require an oscilloscope, although there are some experiments with attaching an accelerator to the motor while doing a frequency sweep.

Of course you could just change settings and see if there is a visual difference, but there are too many settings and combinations to make that realistic.