Fixing car and e-bike batteries saves money and resources, but challenges are holding back the industry

Manufacturer will keep making their card hard to repair cost they want all the money of the customers in original replacement parts. Their cars are specially designed to only be repaired by their own technicians, they want the whole business you know.

Unless it’s a Nissan, then forget a repair – it’s an all out replacement every time. Don’t buy a Leaf.

ChrisFix did it on a Toyota: https://www.youtube.com/watch?v=oAHaYXBFnJo

The whole repair thing should made super easy if we want EVs to succeed.

- Make all batteries use an easily swappable set of standard cell sizes.

- Make battery controllers standardised and swappable.

- …. Er… that’s it.

I heard NIO has this technology already and are looking to standardise it.

But that will never happen because the EV manufacturers couldn’t charge ridiculous amounts of money for proprietary batteries.

God forbid that they concentrate on the quality of the basic vehicle instead.

But you know gubmint regjuleshons are stifling innovation.

That why we need regulators. The market doesn’t magically deal with “Tragedy of the Commons”.

This was posted to one of the communities I sub to a day ago: https://spectrum.ieee.org/flow-battery-2666672335

This would probably be the best option if it takes off.

Because that’s literally a mechanic’s job.

I loved how Renault solved this for the Twizzy (and other cars). You bought the car. You leased the battery for something like 50 euros a month. (Probably more now).

Sure, that sounds expensive, but I suspect it worked out less than replacing the battery after a decade.

Suspect it also helped resale value. The most expensive repair to worry about for a second hand buyer, is the battery. Making that a lease removes that worry entirely. You know exactly how much it’s going to cost.

Of course, having to pay that monthly lease fee for the battery, does make it more obvious that electric cars aren’t necessarily that much cheaper to run than an ICE.

whatever happened to Teslas distributed powergrid? Now that was a game changer, offloading the cost of the battery entirely could have made EVs actually affordable.

I swear, most people on lemmy have their heads shoved so far up their asses about how everyone should get full electric vehicles and that they’re great and have lower maintenance costs just down vote me to hell when I bring anything like this up. I know the tech and I work on vehicles and batteries. It’s dumb to buy a $60,000 vehicle with a 1,200 lb battery that could barely be removed to replace and expensive as hell. The resale value when the battery is about shot is next to nothing, and the “great 8 year 100,000 mile minimum legally required battery warranty” just requires the battery to still work to 70% capacity. Imagine buying a vehicle that is supposed to go 300 miles on a charge, but only goes 230 miles during winter going down to only going 150 miles during winter after 100,000 miles and still not being a warranty issue. My prius started at around 45 mpg, has 240,000 miles on it, and still gets…45 mpg. Hybrid batteries are small enough and cheap enough to be easily replaceable. It crapped out after being about 13 years old and I replaced it myself in an afternoon. It only weighs 75 pounds. No one should buy and keep an EV beyond 10 years old or you risk “being the bag holder” that’s stuck with a 4,500 pound paper weight.

Is it money? I bet it’s money

Mostly it’s money for the consumer. I have a Prius so it might be a little different. But when the hybrid battery goes out costs something like $7,000 to have it replaced. A mechanic in town will repair it for $1000.

Now my car isn’t worth $7000 so if I had to replace the battery then I would just get a new car and this one might end up in the scrap heap. In getting it repaired I have gotten something like 6 more years out of it, at least, and that’s a pretty significant environmental savings.

And that’s essentially what the article is saying.

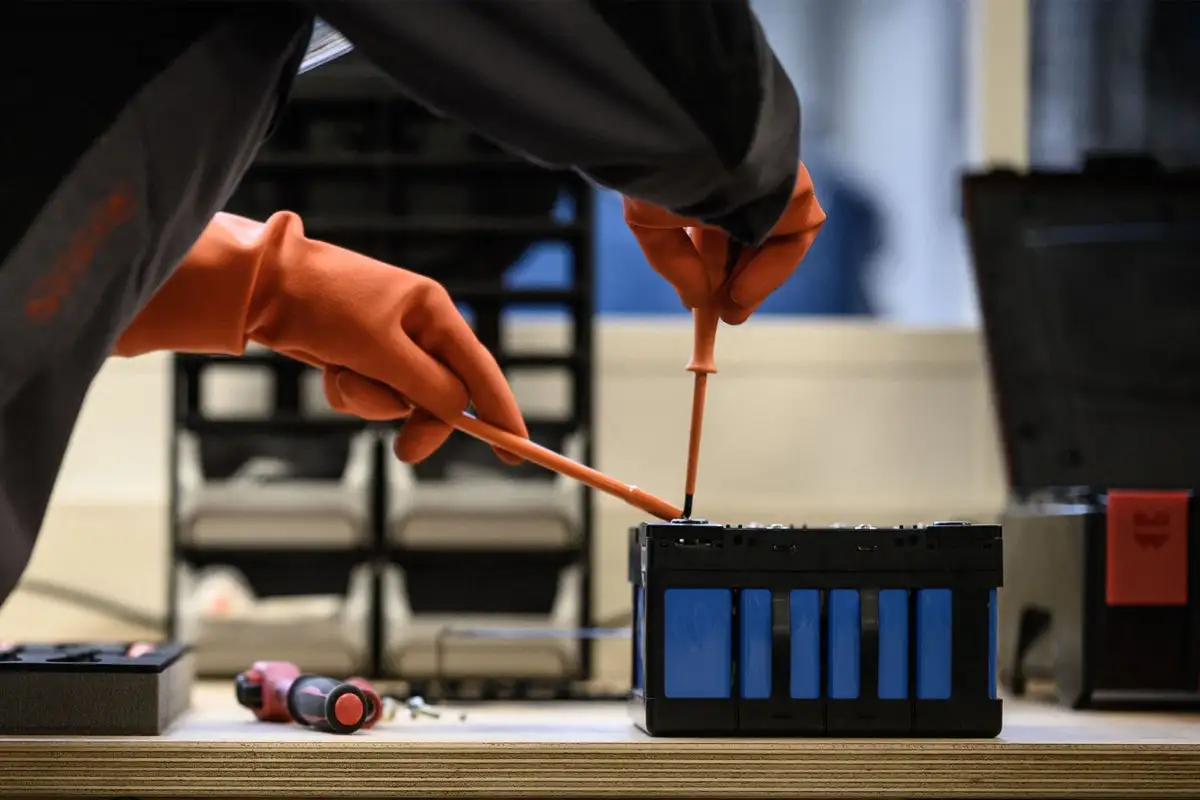

Danger, Danger, High Voltage!

Although it annoys me that mechanics consider even 400V “high” voltage. HV is supposed to be 1,000V, minimum.

400V is dangerous though. The traditional 12V is not.

Absolutely, but 400V isn’t as dangerous as 1,000V. IEC standards have already established all of this, above 1,000V is HV, below 50V is ELV and generally safe. Automotives have come in and labelled anything above like 24V as “HV”, which is just silly.

Jacking Up a Car Is Dangerous. Here’s Why Mechanics Are Doing So Anyway

I suppose jacking off a car is also dangerous.

You wouldn’t download a car… And if you did, you wouldn’t jack off a car…

Depends. Are you a dragon?

Wasnt there subreddits for that?

Not that I know of.

There is dragonsfuckingcars.

Eh. That’s not really comparable to lithium-ion batteries. Lithium-ion batteries are similar to bombs in that they’re highly dense stores of energy. If something goes wrong and that energy storage medium gets exposed to air, or charging safety feature fail, that’s a fire at best, explosion at worse, and it’s extremely toxic.

A car sitting 6 feet in the air is also a highly dense storage of energy that could be released at any moment. I do get your point, but there are ways to mitigate the dangers associated with working on a pack, and they’re not as volatile as you think. Being exposed to air isn’t going to cause a cell to explode as the lithium is mixed with other chemicals inside the cell to make it fairly inert. The danger comes from short circuits, whether it be a puncture or bridging contacts with something conductive.

Have you ever attached jumper cables to a dead lead-acid battery?

https://en.wikipedia.org/wiki/Lead–acid_battery#Risk_of_explosion

Lead-acid batteries also present a risk of explosion.

https://en.wikipedia.org/wiki/Lead–acid_battery#Risk_of_explosion

That’s why you attach jumper cables to the dead battery first.